Vehicle-integrated solar module specialist Opes Solar Mobility will build manufacturing capacity in Germany. After the subsidiary of Opes Solutions developed its first vehicle integrated photovoltaics (VIPV) solution two years ago, the products have so far been manufactured exclusively in a plant in Changzhou, China.

Electrifying road traffic

The current decision to establish production capacities in Germany is a clear commitment to the future location in the centre of Europe, the company says. Moreover, by focusing on the production of VIPV modules, Opes Solutions is pursuing the goal of meeting the urgent need for a stable supply chain and reduction of CO2 emissions in road transport.

See also: Recycled ocean plastic solar modules for vehicle integration

"The transport industry has traditionally been one of the major emitters of greenhouse gases. Only with advanced electrification concepts can the urgently needed change be achieved," points out Robert Händel, Managing Director of OPES Solar Mobility.

Using solar power directly or storing it

The company focuses primarily on larger vehicles. "Trucks and vans have large surfaces that can easily be fitted with solar modules, as well as increasingly large battery capacities that simplify the use of photovoltaics," says Händel. "The solar energy generated can be used for immediate consumption or also stored - a decisive factor for higher ranges and meeting the energy needs of vehicles. With manufacturing capacity in Germany, we are creating new jobs directly on site and a basis for systematically meeting the demands of the future."

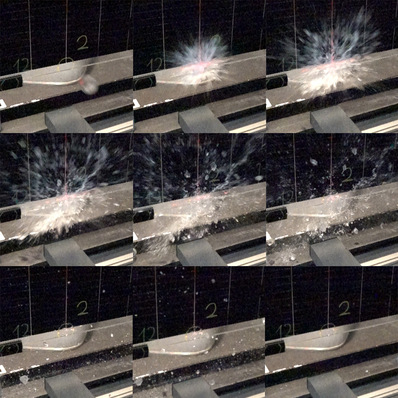

Every solar module is specially tested

The company has not yet announced where the new factory will be located. But it is already clear that the new factory will produce modules with the latest technology from Opes. Among other things, optimised electricity production in the case of shading was the focus of the company's development.

Also interesting: Fraunhofer ISE develops car hoods with integrated solar cells

However, the developers have taken other factors into account and designed corresponding tests to which each module is subjected. These include the behaviour during vibrations as well as the resistance to ice and actually high-pressure cleaners. The bonding of the solar module to various common vehicle surfaces was also extensively tested. The specified bonding allows for optimal aerodynamics, drainage of condensation water and quick installation. (su/mfo)