The Schletter Group developers have optimized the reliable Schletter Tracker, which has been very successful in the market, specifically for easy configuration with ultra-large-format modules. The compact “1P” tracker system is optimized for configuration with on vertical-format module. It uses far less material per kilowatt of power and is much lighter than comparable models on the market.

As stable as a fixed installation

Yet the 1P tracker has the same design advantages as the existing Schletter 2P (two portrait) tracking system. The system works with a patented mechanical self-locking mechanism: In the drive train, there is a Geneva drive at each post that automatically locks the module table at any tilting angle. This mechanical locking system effectively prevents wind-related vibrations (known as the ‘galloping effect’) through the entire range without expensive dampers or similar options needing to be used. In the resting position, the system therefore has the properties and load-bearing capacity of a fixed installation and can be configured for wind speeds of up to 260 km/h.

See also: PV system for 400-year-old monastery in Belgium

In addition, the system is optimized for bifacial modules and can be configured with XXL panels with a side length of up to 250 cm. In the further development of both tracking systems (1P and 2P), the latest wind tunnel reports in line with the latest technical and wind technology developments were prepared and considered.

GMax: large spans, few posts

The Schletter GMax fixed installation open-area system also embodies the concept of consistent material optimization. Thanks to intelligent geometry and high-strength steels, the single-post system achieves large spans and therefore requires comparatively few support posts per kilowatt of installed PV capacity. Thanks to its simple design, it can also be installed quickly and easily.

More flexibility and less ballast on the flat roof

In Anaheim, the Schletter Group will also be presenting its further refined FixGrid Pro flat roof system. With its improved aerodynamics in line with the latest wind tunnel reports, the system needs even less ballast than the classic FixGrid. In this way, with the optimized FixGrid Pro in east-west orientation, the planner can also decide freely where the maintenance aisle will be.

Also interesting: Green Investment Group invests in utility-scale storage developer esVolta

In addition, the Schletter developers have further optimized the system using modular logic. Instead of different module supports depending on the angle of inclination, module size or type of configuration (upright or horizontal), all variants can now be realized with just a few universally applicable components. Firstly, this gives considerable advantages for wholesalers in terms of storage. Secondly, the systems can be planned and installed even faster and more flexibly.

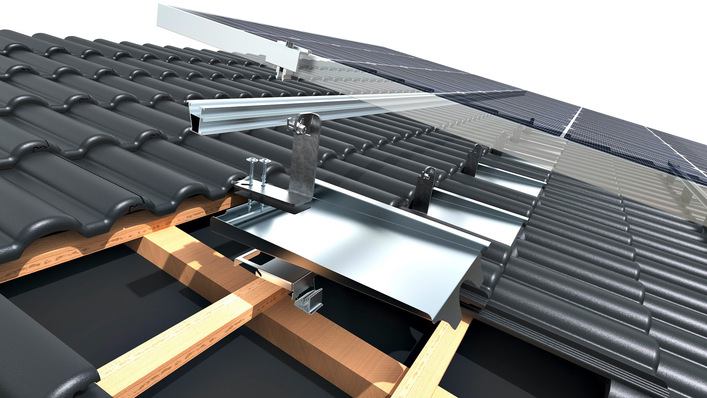

A full range for pitched roofs

Schletter is also showing the essential components of its pitched roof range in the USA for the first time: With the ProLine pitched roof system, a new profile geometry allows for significantly less material usage than with the current Schletter standard profiles. At the same time, the profile can cope with higher loads. The ProLine profiles can also be installed without tools using a single internal connector, which saves time and costs during mounting. A new cross-rail connector ensures a structurally resilient installation. With the “RapidPro” module clamp, all standard module sizes with frame heights between 30 and 47 mm can be fixed throughout the pitched roof and flat roof range, on the principle of “one size fits all”. (mfo)