There are already lightweight modules on the market, but Euronergy is following a new path. What kind of solar cells are you using in your modules?

Martin Green: We use interdigitated back contact cells – the IBC technology.

Why are you using this specific cell technolgy?

They have both of the contacts on the rear of the cell. That gives us the highest possible efficiency. Because there is no shading of the cell as with the contacts on the front. These back contact cells don’t have any metal pattern on the front, and are nice aesthetically. They're very appealing as well as giving you excellent performance.

Stay up-to-date with the the solar energy transition and subscribe to our free newsletter.

The structure of the modules is likewise novel. You use the so-called planar electrical connection or PEC technolgy. Can you tell us about this?

With the PEC technology, the cells are contacted on the rear through a copper sheet. This flexible copper sheet on the rear rather than the ribbons used with conventional modules is a unique way of contacting the cells that's particularly well suited for these back contact cells. This is a very thin foil and it's patterned.

Why does this have to be patterned?

Because of the patterned structure, it can contact the cell in the right areas to separately contact the two different polarities and then connect all the cells in the module in series with one another so that you build up the voltage of the module. Cells give a very high current, but quite a low voltage. So, you have to connect them in series to build up a voltage. This very thin copper sheet performs that very elegantly. It's a technology that's unique, especially in mass production. This technology also avoids contact problems with the cells.

Smarter E AWARD 2025: Energy Transition pioneers shortlisted

Copper isn‘t exactly cheap. Is this a problem?

Most of the conventional modules use a lot of silver. We don‘t need silver to contact the cells and copper is much cheaper compared to silver. Especially now that there's real pressure being put on silver prices through the use in the solar. Importantly, we don’t need any lead either, as used in most other solar panels.

Which additional advantages does this PEC technology offer?

Well, it's proven much more reliable in our durability testing. So it is a much better way of contacting the cells conceptually than the ribbon approach normally used. Since the ribbon contact technology over the decades has given a series of different problems with each generation of cell technology. So this is a much more elegant, integrated way of contacting the cells.

Perovskites to enable new applications for photovoltaics

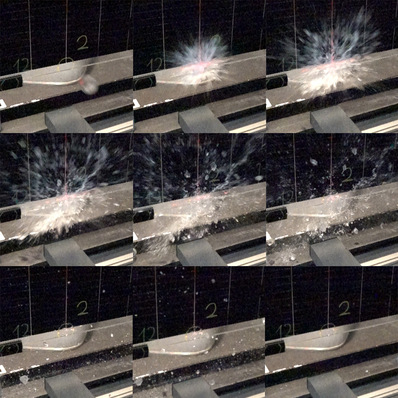

Supposedly, this technology also reduces the risk of hotspots. How does this work?

The IBC cells themselves give you opportunities for spreading any concentrated areas of heat dissipation over the whole cell area. It is easier to design cells that can spread the heat that way. That's one advantage. Then having this copper sheet over the back with a mechanism for conducting heat quickly away from any heated areas. This means there is an advantage in the cell technology, and then the way they're contacted gives you an additional advantage.

Does this approach also help avoid losses due to microcracks?

Yes. It's a gentler contacting approach than the normal ribbon approach. It has the advantage that contacting is done over multiple points. The current can get round cracks with this approach.

So, you can prevent many common issues compared to conventional ribbon technology. Could moisture count as a minor problem?

The cells themselves are actually quite moisture resistant. You really want the modules with the silicon technology to be permeable to moisture because there's acids and things that are generated over the life of the module that you want to get out. You want the module to actually breathe. That's the design that they've used with silicon modules over the decades. The modules have shown excellent durability over that period. Some of the other solar technologies like cadmium telluride and the perovskites that are under development now are very moisture sensitive. You need to try to seal them up so they're completely impermeable to moisture.

How does PEC technology impact the flexibility?

The main thing is avoiding the use of glass. It's very important. There's a specially developed polymeric cover used rather than the glass. Additionally, the copper sheet adds additionally to the flexibility of the module so that you don't run into the problems with the normal ribbon interconnects. It is a combination of those two things, getting rid of the glass and having this copper sheet connection approach that removes some of the problems with normal modules if you try to flex them.

Interview by Sven Ullrich.

Learn about the applications that Euronergy is targeting with its new modules in the first part of the interview with Martin Green.