For Part 1 of this series, click here.

Part 2:

We regard project planners, solar installers and technical operators as partners. With our help, they should be able to work more economically and withstand the increasing cost pressure in the industry. Our software reliably determines when an asset is not delivering optimum yields. Whether it is the insulation resistances, mains frequency, mains voltage or the MPP, everything will flow into the comprehensive analysis and enable a fast reaction. Solytic's vision is to create an efficient marketplace that brings technical operators and equipment owners together to get the most out of their equipment.

For example, if one of the inverters in a system with a total of three inverters runs hot, the predicted output is not correct and will deviate from the normal values. In this case, our monitoring software immediately responds and informs the operator, often by e-mail. Because it can also precisely determine the fault, it saves the technician on-site time, and they can quickly repair the inverter so that the damage incurred for the asset owner is kept to a minimum.

Everything from a single source

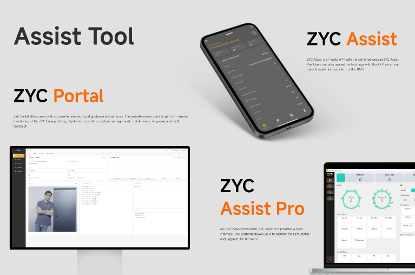

Solytic can already offer basic monitoring for commercial assets, which records actual data and sends out tickets (i.e. small reports). E-mail messages are generated directly from the system via a communication module and relevant errors are automatically forwarded to the asset owners or operators. Several assets can be viewed and monitored simultaneously in the customer portfolio. We’re currently developing new features and are working on integrating further technical devices so that the market is completely covered.

It is particularly important to us that the self-explanatory user access is maintained and that our customers can continue to use the portal intuitively. The dynamic market environment requires the software to adapt to the ever-changing needs of its users, not the other way around. In doing so, we follow our customers' priorities: Functions that are used more frequently and have a high automation potential are right at the top of our developers' implementation list.

Cost-effective monitoring

Artificial intelligence and machine learning will radically change the work of technicians in the future. Solytic wants to use the potential of digital technologies and automation to further reduce operating costs. Alarm messages will be precisely set and parameters will be automatically adjusted to suit the asset. The monitoring of the technical systems will be adapted in detail to suit local conditions. As a result of this development, technical operators will be able to support considerably more assets at the same time.

According to our research, the market costs for monitoring currently average at over €0.80 per kilowatt per year. Solytic can offer the same service for just a quarter of the amount (i.e. €0.20 per kilowatt per year). The minimum price for the service is €60 per customer per year. In order to register the asset, a one-time set up fee of €0.50 per kilowatt of output is added.

Have creeping errors on the screen

Although not every development can be anticipated in advance, background changes can be recorded using artificial intelligence. Small deviations from normal values do not necessarily trigger an alarm, but they can cause economic damage. Automatic tickets are only generated when the deviation is system-relevant. With Solytic, however, trends are spotted and continuously checked for their severity in the background. It is comparable to human intuition.

Programming a computer system to be intuitive is not an easy feat. Measuring the solar power yield is a demanding task, as the software only receives the raw data from the inverter and no exact data from the feed-in metre. A precise analysis requires more detailed data than what is provided by the inverter. For this reason, Solytic collects additional external information, such as weather data and asset metadata. This addresses questions like: How many modules are in a given string? How are they interconnected? What is their orientation and inclination? What kind of inverters and modules have been installed?” (mfo)

The series concludes with Part 3, which is now available.

About the author Johannes Burgard:

Johannes Burgard, founder and CEO of Solytic, is responsible for product development and strategic direction. Prior to this, Burgard managed projects in the context of Industry 4.0 in an international production environment at CLAAS and Airbus. Burgard holds a degree in engineering from RWTH Aachen University and an MBA at the ESADE Business School.

For more articles on the planning and operation of solar installations, please click here.

Stay informed, subscribe to our twice-weekly newsletter.

Register here: https://www.pveurope.eu/newsletter