The Vertex Super Factory project in Yiwu has progressed rapidly, completing the infrastructure and move-in of the equipment in just 112 days. On July 29, Trina Solar’s Yiwu production base started production of 4GW modules for the first phase. The groundbreaking ceremony for the second phase of 4GW modules was held on the same day.

According to the company, this is the world’s first factory base producing innovative and ultra-high-power products of 210mm silicon wafers, cells and modules. The factory has marked an important milestone in the history of Trina Solar while taking the industry to a new height.

Vertex Super Factories also under preparation in other countries

In addition to Yiwu, Trina Solar has also built a Vertex Super Factory in Suqian. The Suqian 210mm-module plant has a capacity of 12GW, where the first and second phases are now operating. The third phase, meanwhile, is progressing rapidly. Groundwork is expected to be completed by the end of 2020 and production will start in the first quarter of 2021. More Trina Solar Vertex Super Factories in other countries are also under preparation.

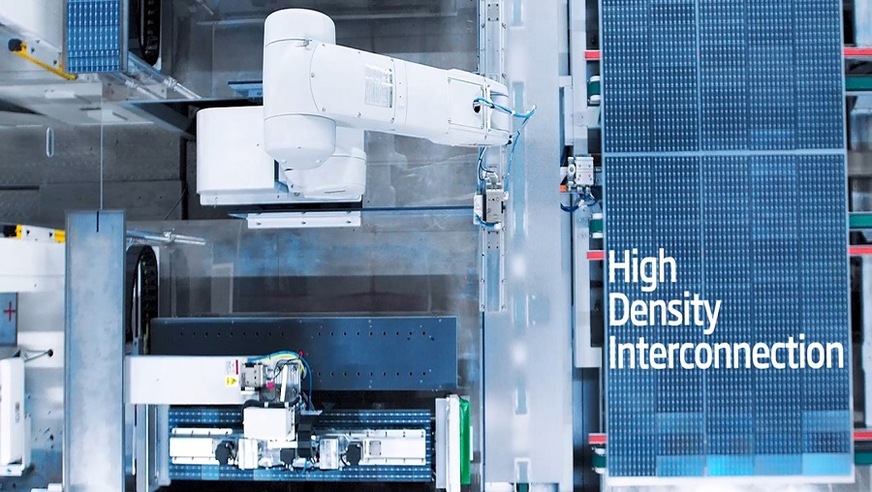

In terms of module technology, Trina Solar’s Vertex series modules incorporate several state-of-the-art technologies such as non-destructive cutting, high-density interconnection, and multi-busbar.

Low-voltage, high-string-power design

Vertex 600W+, 550W series modules adopt the innovative design with low voltage and high string power. This design can effectively reduce the number of strings, and the corresponding mechanical connections such as racking structure, DC cables, junction boxes and other electrical connections can be effectively saved, and thus the system cost, thereby adding more value to customers. At the same time, the auto bussing machine equipment has successfully integrated special high-precision placement and automated functionality.

Multi-busbar technology with precisions in millimeters

Trina Solar say it is the first company in China to develop and realize the industrialization of multi-busbar technology (MBB). MBB modules use precise positioning and welding solutions to nail down to millimeter-level precision. Round ribbons are applied to improve the secondary optical utilization of the ribbon area. The power, therefore, can be increased by more than 5W compared with five-busbar modules, so that the conversion efficiency of Vertex modules can be boosted as much as 0.3%.

Trina Solar

The remarkable performance of Trina Solar’s 210 mm modules – high efficiency, high power, high reliability, and significant reduction of BOS and LCOE costs – is made possible by a combination of innovative technologies, reflecting Trina Solar’s 23 years of technological and innovative advancement.

High level of automation and highly efficient productivity

Trina Solar produces Vertex modules with completely automated equipment. The brand-new welding machine can weld at a speed of about 4,000 pieces per hour – currently the fastest in the industry. The laminator is also extremely advanced in terms of power saving and its production speed. The Vertex Super Factory can directly detect product defects through automatic visual inspection equipment using artificial intelligence technology, effectively improving inspection efficiency and product yield.

Compared with previous workshops, Trina Solar’s fully automated workshop can reduce the workforce by about 25% per GW. This is a significant cut in labor-related costs, compared to the current 166mm or 158mm-module factories.

Sharing data with customers for smart manufacturing in the 600W+ era

“We already have a complete set of smart factory solutions and smart manufacturing data centers", said Yang Xiaojun, General Manager of Trina Solar’s Yiwu Super Factory. “Data can help in different areas, such as monitoring the production status of all production facilities, order tracking, and customer order completion. It can be shared with the company’s internal and remote customers in real-time. For customers, they can view the production process and key parameters of the product anytime, anywhere.”

Did you miss that? Longi, JA Solar and Jinko Solar focus on 182mm modules

As one of the initiators of the 600W+ Photovoltaic Open Innovation Ecological Alliance, Trina Solar says it stands at the forefront of the new photovoltaic era. (hcn)