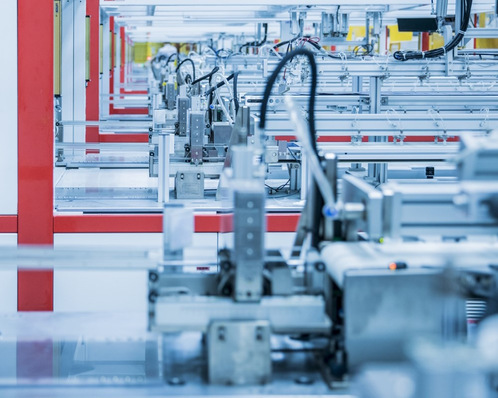

Together with Asys automation systems, Fraunhofer ISE has developed a new manufacturing system that produces solar cells 1.5 times faster. The central innovation is the metallisation of the solar cells. This is because the busbars and cell grids are applied to the solar cell by screen printing. In the new line, the developers have replaced the flat-bed screen printing process that was common until now with a rotary screen printing and flexographic printing process.

0.6 seconds per cell

With the new line, the developers and researchers were able to metallise the solar cells in a cycle time of only 0.6 seconds per cell. "Metallisation by screen printing is limited by the process to a throughput of currently around 0.9 seconds per solar cell and track," says Florian Clement, head of the Production Technology - Structuring and Metallisation department at Fraunhofer ISE, in comparison to the previous process. "Printing is thus a bottleneck in the production process of silicon solar cells, and also in the coating process of piece goods components in many other industries," he explains, referring to the other possible applications. This is because rotary screen printing is also suitable for the metallisation of other electronic components used in power electronics, among others.

Precisely coated

In order to achieve the targeted printing speed, the researchers, together with the Swiss machine manufacturer Gallus Ferd. Rüesch, a subsidiary of Heidelberger Druckmaschinen, have developed a new transport system with a high throughput. The wafers are placed in so-called shuttles and transported through the system at high speed and with high precision, while being precisely coated with ultra-fine structures.

Also interesting: Fraunhofer ISE settles in patent disputes over inverter technology

The new plant, however, is so far only a demonstrator to show that the technology also works for solar cells. But with this concept, they have already been able to show that they can drastically speed up the printing process. "The system has the technical potential to double the throughput compared to screen-printing systems," Andreas Lorenz, project manager at Fraunhofer ISE, holds out the prospect. (su/mfo)