The photovoltaics industry looks set for dynamic development in 2017. Production technology companies are responding by investing heavily in new facilities for cell and module production or upgrades to existing manufacturing lines. Companies in China and India alone have announced plans to expand production by 17 gigawatts (GW) each in 2017.

Higher efficiency and cost reduction

The USA, Europe, Saudi Arabia and Iran are also building new production facilities, and the German Engineering Federation (VDMA) reports that the order books of German manufacturers of facilities, components and machines are as full as ever. The main focus is on technologies for more efficient solar cells, such as PERC cells (passivated emitter rear contact) and PERT cells (passivated emitter, rear totally diffused), as well as heterojunction technology. Furthermore, new manufacturing and automation systems are expected to reduce operating and material costs and ensure an increase in productivity, and thereby more competitive prices.

PERC and PERT solar cells

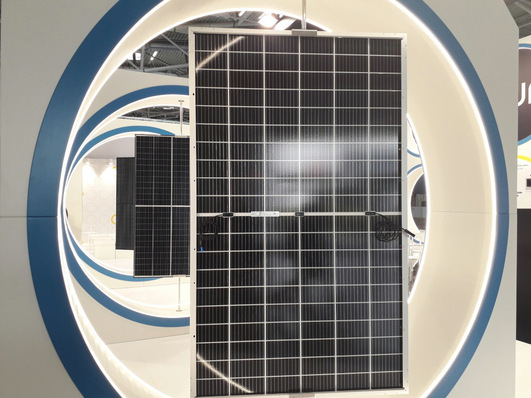

Innovative processes for manufacturing highly-efficient cells hold considerable promise: Both PERC cells, which increase the passivation on the rear side of solar cells, and PERT cells increase efficiency, thereby reducing the module costs per KW of output. As a result, manufacturing facilities for such efficient modules are in demand and offer a significant competitive advantage – not only for plant constructors, but also for PV manufacturers who, on these grounds, are retrofitting existing manufacturing lines with new technologies in addition to constructing new facilities.

Heterojunction technology

Heterojunction technology is also expected to set new records for efficiency. This cell concept combines crystalline and amorphous solar technology to achieve extremely high efficiency levels. Suppliers of production facilities for double-sided (bifacial) solar cells and modules anticipate a 30% higher yield compared with the yields achieved by the cells available up till now. The industry expects to see progress not only from new cell concepts, optimized contacts and improved module concepts, but also from higher quality silicon wafers.

Intersolar Europe Conference

Falling module prices put pressure on plant constructors to boost efficiency in manufacturing as well. Here, the industry is searching for approaches which save costs and materials, and uncovering new potential for savings, for example by automating processes. Experts will be discussing the availability of options in this area, as well as locating further potential opportunities for growth and scope for greater efficiency at the Intersolar Europe Conference, which takes place in parallel to the exhibition.

The future of crystalline silicon technology

More than 30 sessions will address the future of the photovoltaics industry: Attendees can find out more about technical achievements and new challenges for module production, receive new impetus for investment and gain insights into the global PV markets, bring themselves up to speed on solar cell manufacturing with crystalline silicon, or discuss the implementation of the climate targets set at the 21st United Nations Climate Change Conference (COP 21).

The VDMA will be presenting the results of the 8th International Technology Roadmap for Photovoltaics at Intersolar Europe. Interested attendees can find out more about the technological trends in crystalline silicon photovoltaics, and have the opportunity to discuss potential improvements and standards with research institutes, suppliers and users at the event. Intersolar Europe 2017 will take place from May 31–June 2 at Messe München. (HCN)

Stay informed, get our weekly newsletter. Register here: http://www.pveurope.eu/Newsletter

Related news:

http://www.pveurope.eu/News/Markets-Money/Intersolar-Award-2017-and-ees-Award-open-for-applications