Back in 1961, the first Light-Emitting Diode was invented by Robert Biard and Gary Pittman: small, and limited to Infrared light, it was a modest beginning. 58 years later, and the LED industry has grown exponentially, flourishing and advancing at every turn. With nearly 6 decades of innovation, the industry is well-established, and there have been huge gains in technology even recently - especially in the areas of stability and increased power output.

With all the advances in the LED lighting industry, LED based simulation of solar irradiation has become a new alternative. It’s vital to stay knowledgeable about advances, and to determine which LED is the best suited for our particular needs. Beyond that kind of decision, we must have the capacity to properly control their performance and use. It’s a new playing field, and Avalon ST has taken the challenge. The Swiss company is now at the cutting edge of LED simulator technology.

Just begun to explore the real value of LED solar simulators

Pulsed Xenon based solar simulators have been the best and the most reliable prime choice for manufacturers and laboratories for the last 30 years. However, “We’ve only just begun to explore the real value on LED solar simulators are capable of,” says Marcos Barrigon, (Company operation & Business development director) “As a team, Avalon ST believes that LED will take over in labs and then on production due to the many advantages it brings in regards to Xenon technology.”

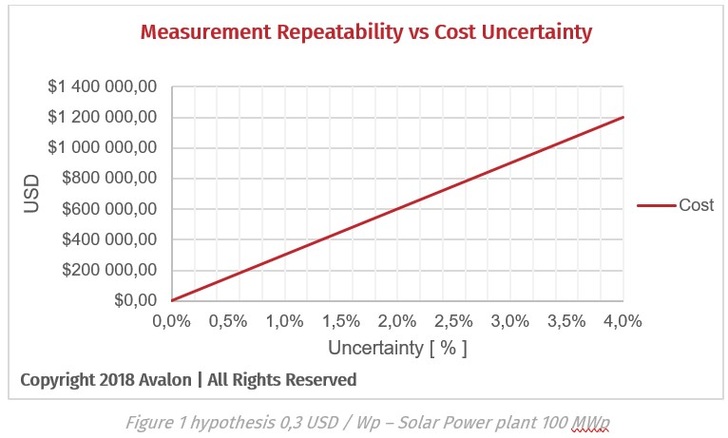

The current module level uncertainties are above +/- 1.5% for leading labs but usually manufacturer uses calibration samples which are measured with an uncertainty above +/- 2%. Then adding their own uncertainties, it reaches beyond

+/- 3% k=2 and that is with using state of the art xenon systems. The incoming new PV technologies are more complex to measure and this uncertainty will increase accordingly. You can think of if you were measuring time, distance, or your portfolio with such an uncertainty.

High-efficiency PV technologies require more accurate measurement

With the recent changes, it’s important to be ready for the future. The PV technologies are changing quickly from standard crystalline to hetero-junction modules, bifacial, n-types and others. The first steps to this transition have started to roll out: the monoPERC is already well implemented in new production lines, with almost 50% of the market share. Warns Barrigon: “Be on time for the hetero-junction and jump in on this transition. It’s time to move!”

Indeed, the game has changed. Existing Xenon solar simulators are reliable and have provided an accurate measurement for the standard crystalline modules. However, for the monoPERC, they are starting to fall behind - almost all Xenon solar simulators have to use some algorithm in order to perform accurate measurements and “hot-fix” the xenon technology short-comings. The industry is improving and innovation is critical to support the market. At Avalon ST, their group is energized and ready to lead the industry. "We target measurement accuracy,” affirms Barrigon, “Our team has developed a whole new approach to the solar simulator playing field.”

Evolving LED system technology

Current LED system on the market have given a somewhat mixed feelings about the technology. Bad & peaky spectrum, Instability, high cost, heat. These were the first generation of system and were not representative of the potential of the technology. LED system needs a whole new, more complex and different, regulation electronics than previous technologies. At Avalon ST, we have identified and solved these short-comings and surpass Xenon based system in almost all aspects and particularly in spectral deviation which is 30% lower than the best existing Xenon technologies from 300-1200nm.

Beyond raw specs, LED offers dreamed-of capabilities previously impossible with Xenon technologies: Long pulse, Irradiation starting from near-zero, multi irradiation levels, modulation of spectrum, quantum efficiency evaluation, uniformity modulation, all which can be combined in a single flash. Combined with a thermal chamber, LED simulator are not only an IV measurement tool but a much more advanced characterization system.

Higher investment costs pay off

Thanks to the number of advantages that a LED solar simulator offers, the investment cost only appears to be more expensive. But, is it the right way to assess the costs for industrial equipment? Barrigon offers an example: “In our personal lives, we’ve all been tempted by the cheap purchase price,” he says, “but in the end that cheap initial investment turned out to be the most expensive. Be smart about your simulator investment, especially when it’s the final measurement down the line!”

Recently, for cost-saving purpose, we have seen major manufacturer using cheaper, less accurate systems. An increase of measurement uncertainties caused by lower repeatability causes a major capital risk for buyers and solar power plant investor as the factory measured power is directly related to the plant power output and profitability, which are often underperforming. This leads to complex and expensive plant assessment by third parties to then claim underperforming panels, damaging the reputation and trust of the manufacturer and the plant owner. Control of the manufacturer measurement system before placing large order is critical in order to reduce the capital risk. LED based measurement systems will, at term, reduce the overall measurement uncertainties. (HCN/Marcos Barrigon)

Stay informed, get our free newsletter twice a week. Register here

Join our pv Guided Tours at The smarter E Europe 2019 (Intersolar Europe, ees Europe, Power2Drive, EM-Power), register here