This marks two important milestones in the processing of solar modules and closes the cycles of the two recyclable materials. The recycled material recovered from the solar glass is of such high quality that it can be used again in high-quality melts in the glass industry.

This means that it no longer needs to be used as a substitute material in the building materials industry. The glass cycle is sustainably closed. Reiling has spent years researching how to process the used glass so that it can be added to the mixture for new, optically sophisticated glass.

See also: New centre for solar module recycling in Münster, Germany

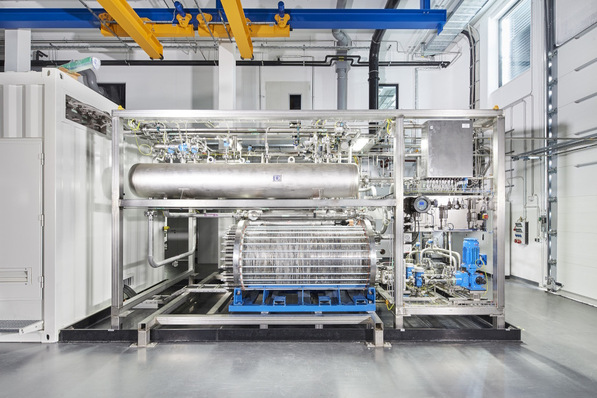

A crystalline photovoltaic module contains three to five per cent silicon. Reiling has developed a mechanical recycling process to recover this proportion. It is the result of the EOL Cycle project, which was funded by the German Federal Ministry of Education and Research between 2015 and 2019.

Also interesting: Schletter Group releases first CSR report

This process has now been transferred to an industrial scale. It remains to be seen in which industries the recycled silicon will be used. Possible applications include metallurgical processes, battery production or as solar silicon. (HS/mfo)