The installed photovoltaic capacity is growing rapidly worldwide. Photovoltaic systems with a total output of around 600 gigawatts now supply clean and cost-effective electricity – replacing around 600 medium-sized coal-fired power plants. SMA Solar Technology AG and Infineon Technologies AG support this growth trend with the latest generation of innovative solar inverters based on silicon carbide (SiC). The new semiconductor material reduces the system costs for inverters and increases their efficiency. The production costs for solar power are thus further reduced.

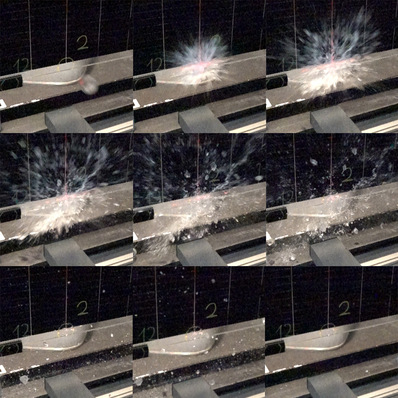

With the Sunny Highpower PEAK3 from SMA, available since 2019, decentralised photovoltaic power plants can be planned flexibly and efficiently up to the megawatt range. The basis for this is the compact design for 1500 volt DC, which delivers an output of 150 kilowatts per unit. This is made possible by SiC technology from Infineon: Six power modules of the type CoolSiC EasyPACK 2B and 36 gate drivers of the EiceDRIVER family 1ED20 convert the direct current generated by the solar cells into grid-compatible alternating current – at an efficiency of over 99 per cent.

Silicon carbide offers advantages for the overall system

“Silicon carbide enables us to build the inverters compact, powerful and reliable,” said Sven Bremicker, Head of the Technology Development Centre at SMA. “In the Sunny Highpower PEAK3, the CoolSiC modules almost double the specific output from 0.97 to 1.76 kilowatts per kilogram. Due to the compact design, the inverters are much easier to transport and much faster to install.” The advantages of a decentralised plant layout can thus be combined with those of central inverters. Expansions are easily possible even after the photovoltaic power plant has been commissioned.

“SiC-based power semiconductors are more expensive than silicon solutions,” said Peter Wawer, President of the Industrial Power Control Division of Infineon. “But thanks to the electrical properties of the material, this is more than offset at the system level. Faster switching speeds and better efficiency allow smaller transformers, capacitors, heat sinks and ultimately packages – thereby saving system costs. We are very proud to have convinced SMA of the advantages of our innovative SiC products and to support volume production.” Not only photovoltaic systems profit from these advantages. Demand for SiC-based solutions from Infineon is also growing in other industries and for applications such as uninterruptible power supply and charging infrastructure for electric vehicles. (mfo)