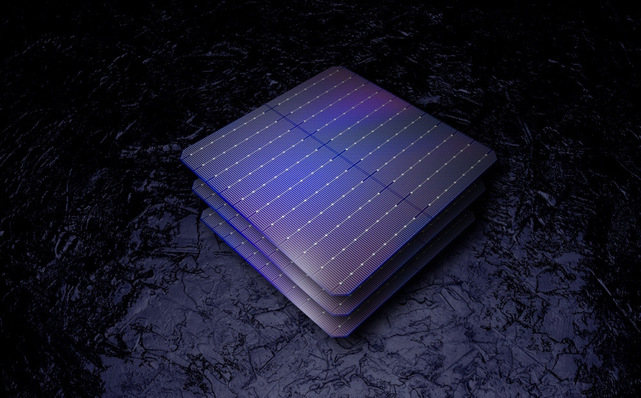

Unprecedented precision and speed are the outstanding features of a novel high-throughput system for the metallization of silicon solar cells and other functional printing applications. The system is able to realize high-precision coating processes using rotary screen printing and flexographic printing with a throughput corresponding up to 8000 components per hour on an industrial scale. The demonstrator machine was developed by a project consortium under the joint leadership of the ASYS Automatisierungssysteme and the Fraunhofer Institute for Solar Energy Systems ISE. In addition to solar cells, the system enables high-precision printing on single components, e.g. for applications in the field of hydrogen technology, sensor technology or power electronics.

Main focus rotary printing methods for silicon solar cell production

The main focus of the Rock-Star research project was the evaluation and development of rotary printing methods for silicon solar cell production. This project has now been successfully completed upon the realization of a novel demonstrator for the high- throughput coating of silicon solar cells and other electronic components. The new system features a newly developed high-throughput transport system, in which the components to be printed e.g. silicon solar cells, are transported on autonomous shuttles with high speed and precision through the rotary printing units of the Gallus Ferd. Rüesch, a Swiss printing machine manufacturer which is part of Heidelberger Druckmaschinen. Finest structures can be printed directly on the components. Depending on the specific requirements, a flexographic printing or a rotary screen printing unit can be used for the printing process.

Speed up to 600 mm/s

The modular system design also facilitates other printing and coating processes such as multi-nozzle dispensing and gravure printing. The novel transport system conveys the components with speeds up to 600 mm/s and ensures high precision printing. Compared with the current state-of-the-art machines in, e.g. solar cell metallization, this corresponds to a theoretical throughput increase of 100% per production line. "The newly developed system is a direct answer to industry’s need for innovative technologies which significantly increase productivity," explains Florian Clement, head of the Department of Production Technology - Structuring and Metallization at Fraunhofer ISE.

Fraunhofer ISE

The potential applications of the new system extend far beyond the metallization of silicon solar cells. While the overwhelming majority of printing and coating systems on the market operate on the roll-to-roll printing principle and are thus limited to web- based substrates, this system addresses the high-throughput printing of unit-load components such as solar cells, printed circuit boards, chip cards and a multitude of other components with previously unknown precision and speed.

Innovative coating processes – cost savings

The aim of the Rock-Star project was to evaluate the use of rotary printing for the production of silicon solar cells and to develop appropriate metallization processes. The project consortium succeeded in revolutionizing a cost-intensive process step - front and backside metallization - in silicon solar cell production by developing innovative coating processes and system concepts. Within the project, it was successfully shown that the front and rear side metallization of highly efficient PERC (passivated emitter and rear contact) solar cells can be realized using flexographic and rotary screen printing. "PERC solar cells metallized with rotary screen printing achieve a similar quality and electric performance as reference solar cells metallized in a flatbed screen printing process, yet they open up a greater potential for cost savings due to the significantly higher throughput," explains Andreas Lorenz from Fraunhofer ISE.

Using SmartWire connection technology

"We were also able to produce the first functioning demonstrator modules consisting of solar cells with rotary printed metallization and using SmartWire connection technology for the solar cell interconnection. We see great potential in this technology for a wide range of applications, from the metallization of solar cells up to high- throughput coating of functional structures for sensors, SmartCards, fuel cells and other applications," Lorenz says.

The research in the Rock-Star project was funded by the German Federal Ministry of Education and Research (BMBF) as part of the funding initiative "R&D for Photovoltaics." The research project evaluates high-throughput rotary printing processes for the cost-efficient metallization of Si solar cells and develops suitable equipment technology. The development of such metallization processes requires highest precision in the design and production of corresponding printing units

Several industrial and R&D partners

The company Gallus Ferd. Rüesch AG enriches the consortium in this respect with its decades of experience as a leading global manufacturer of high precision rotary printing units and industrially produced Gallus Screeny P-Line screen printing plates featuring the unique Flow Shape topography. ContiTech Elastomer Coatings GmbH develops laser-engraved printing plates with micrometer precision for the research project. Scientific and technological support for the project is provided by Fraunhofer ISE and the Institute for Printing Processes and Printing Machines (IDD) of the Technical University of Darmstadt. The companies Hanwha Q Cells and Kurt Zecher as associate partners support the project with their expertise in the field of solar cell and solar module manufacturing and anilox rollers. The work in the Rock-Star project is being continued in the Rock-IT project, funded by the Ministry of Economic Affairs and Energy BMWi. (hcn)