The German Efficiency Guide for domestic storage has been available for some time now. What insights has the industry gained since then?

The Guide has helped us to understand that the efficiency of domestic storage systems very much depends on the usage profiles and the integration of the storage into the installation on site. Not only the technical quality of the devices, but their correct design and adaptation to the specific application play an important role. The efficiency depends, among other things, on what percentage of its capacity the storage system is currently using. Accordingly, it is relevant how long it remains in a state of high or low efficiency. It was also noticed that manufacturers put a varying amount of importance in achieving the lowest possible stand-by consumption.

In the case of commercial storage, the load profiles are generally known. What about private end customers?

In the project-based business, the load profiles can be measured and the storage unit can then be adapted in a modular way. This is usually not worth the effort for domestic storage. Private end customers usually have compact complete systems installed that are already designed for typical cases. Their efficiency can be determined with one or more standard profiles. A test profile may not exactly fit a certain customer, but at least it serves as a uniform foundation for comparison between products.

You spoke of simulation. Have the simulations proposed in the Guide proved their worth?

We have also learned what the limitations are, especially with products capable of learning. This is a process of understanding. The main purpose and greatest benefit of the Efficiency Guide to customers is to identify the black sheep among the storage manufacturers, i.e. the providers of storage systems that have poor efficiency or high stand-by consumption. The advantage of finding the best among good systems that differ only slightly may be eliminated if, for example, the second-best fits better to your usage profile.

The Guide is a voluntary commitment of the storage industry, not a technical standard. What gaps still remain in the standardisation of electricity storage units?

In Germany, we are already very far advanced when it comes to this and in terms of safety standards for domestic and stationary storage. Gaps exist only in details. Thanks to the VDE-AR-E 2510-50 application rule, we are very well-positioned, also with regard to international compatibility, in order not to create market barriers. It becomes more difficult with international standards if you understand the storage units as appliances with integrated batteries. Here, there is still some issues to be resolved.

For example?

There are sufficient standards on the electrical safety of the systems. An example where ground needs to be gained is electromagnetic compatibility. The European Union’s EMC directive applies here, the general application of which is clear. However, it has not yet been determined, for example, which function of the battery management system (BMS) needs to be interference-resistant and how. The consideration of the BMS software in terms of functional safety is also nowhere near as settled in the standards as, for example, for the control software in inverters. Professionals get it right, nevertheless, but the differences are not yet discernible for customers by comparing the standards adhered to.

Are these gaps narrowing?

We are on the right track. Either existing standards are adapted, or these issues are included in new draft standards. Standardisation for battery systems is very similar to that for inverters, which have been on the market for several decades.

What is the state of the art in terms of standardization overseas?

Very different. It has to be said that we in Germany have reached an exemplary level. In Australia, for instance, something went awry; for a while, only outdoor equipment was to be permitted there. In France, a cycle test is meant to prove the safety of storage systems. There is a lot of committee work to be done. A lot of mistakes are being made overseas that we have already gone through in Germany. (HS)

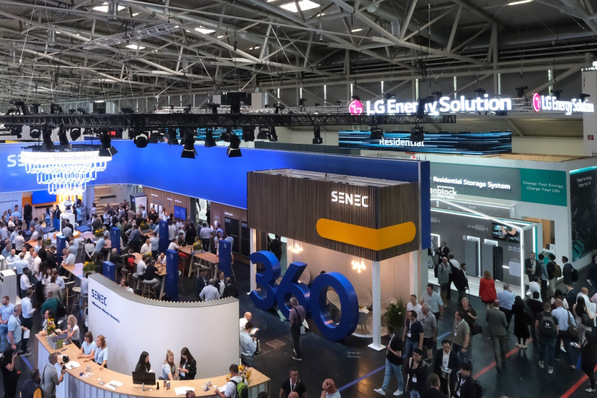

What was new at the Intersolar and the EES Europe 2018 in Munich? Watch our expert’s movie clips here:

http://www.pveurope.eu/Videos/pv-Guided-Tours-videos-2018

Stay informed, get our newsletter twice a week.

Register here: http://www.pveurope.eu/Newsletter

Read more about solar modules.

Read more about solar mounting systems.

Read more about solar energy storage.